Week 2 Blog

Monday Feed Back

FMP- Look into vehicle rigging, and then how to get them

running in engine. This way my portfolio shows that I know how to make game

ready vehicles, not just static meshes.

Finished Low Poly

It’s time to organise all the meshes and prep for the high

poly. This means, aligning all the pivots, resetting all the X-Forms, checking

for n-gons, collapsing symmetry (welding the seams) and generally tidying up

geometry.

Tuesday

I looked at another students work. I have come to the realisation

that my model is not up to par and still needs allot of work. My model is only

just within the budget and has an extremely low poly interior, no mirrors, no

handles and generally very few of the surface details. The model I have just

seen has all of these features done to a high quality and is still within

budget.

Redoing these part will set me even further back, I really

had to start creating the high polys today. But when comparing my work with the

other, my model currently is appalling. Leaving it as it is would be handing in

terrible work. My mesh has to be altered drastically.

The problem here arose when beginning to chamfer the basic

block out of the forms. When working to a budget you have to guess how many

chamfers to apply to an edge from the start, then as you continue to model you

have to hope that the chamfers will not eventually put you over budget. I

guessed way to high, my model quickly became over budget. As a result I started

cutting corners with the quality of the smaller assets, or simply removing

these aspects of the Roller. But now viewing a mesh with all the details included

and to a high quality, I realise that my mesh with all these features missing

will not be up to par.

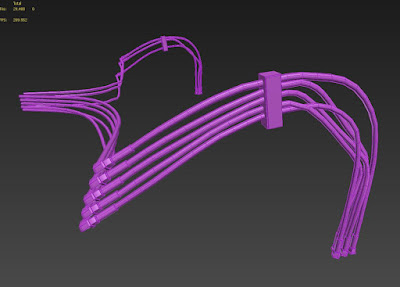

An Example

of one of the areas that I went wrong

These are my wires they are a massive 7.500 tris, and they

could actually do with a few more loops to smooth out some of the bends. The

Mesh I have been comparing mine to has more loops running through there mesh so

that they have a cleaner curve, but they are also under half the budget of

mine. This is because when they initially created there wires they used a less

round tube. I picked a 9 sided cylinder, they picked 5 or 6. This has had a huge

impact on the budget of my model. These really should be done again. But this will take allot of time to remedy.

If I can potentially save up to 3000 Tri's in this area alone, I might be able to just alter these. This might give me enough tries to improve the existing external features as well as may be adding more. If not I will have to change other areas also.

At this point decisions like this will determine weather I create a bad mesh but finish. Or weather I create a good mesh and don't. Just altering the wires, if this does give me enough tries to complete the model, the mesh over all will still be poor. This means I will still loose marks here, and most importantly I will not be able to put this finished asset into my portfolio.

At this point decisions like this will determine weather I create a bad mesh but finish. Or weather I create a good mesh and don't. Just altering the wires, if this does give me enough tries to complete the model, the mesh over all will still be poor. This means I will still loose marks here, and most importantly I will not be able to put this finished asset into my portfolio.

What

I have learnt

For an

asset of this complexity 30.000 tries is sufficient to make a good model, but

it is not allot. You still have to be cautious with you chamfers.

When

creating wires, realise that these can quickly become extremely expensive.

Don’t

get carried away with the good work practice of unwrapping meshes as you create

them. For this kind of asset you’re better off creating the whole asset and

then unwrapping. Only duplicated meshes

need to be unwrapped immediately. During this project I have already unwrapped the

same mesh multiple time due to further alterations. This has wasted huge

amounts of time. The same goes for applying smoothing groups.

No comments:

Post a Comment